Ipayipi Elimise Okukhethekile

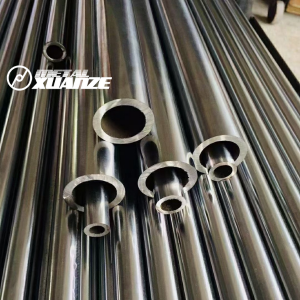

Ipayipi elimise okukhethekile liwuhlobo lwepayipi lensimbi elingenamthungo elenziwe ngomdwebo obandayo.Ipayipi lensimbi elingenamthungo elimise okukhethekile yitemu elijwayelekile lepayipi lensimbi elingenamthungo elinobunye ubujamo besigaba esiphambanayo ngaphandle kwepayipi eliyindilinga.Ngokusho kokwakheka okuhlukile nobukhulu besigaba sepayipi lensimbi, ingahlukaniswa ngezinhlobo ezintathu: ipayipi elilinganayo lodonga olumise okwensimbi engenamthungo, ipayipi elingalingani lodonga olumise okwensimbi engenamthungo, ububanzi obuguquguqukayo ipayipi lensimbi elimise okukhethekile.

Ipayipi lensimbi elimise okukhethekile elingenamthungo lisetshenziswa kabanzi ezingxenyeni ezihlukene zesakhiwo, amathuluzi nezingxenye zemishini.Uma kuqhathaniswa nepayipi eliyindilinga, ipayipi elimise okukhethekile linomzuzu omkhulu we-inertia kanye ne-modulus yesigaba, futhi inokugoba okukhulu nokuphikiswa kwe-torsion, okunganciphisa kakhulu isisindo sesakhiwo futhi yonge insimbi.

Ukuthuthukiswa kwepayipi elimise okukhethekile ikakhulukazi ukuthuthukiswa kwezinhlobonhlobo zomkhiqizo, okuhlanganisa ukuma kwesigaba, impahla kanye nokusebenza.I-Extrusion, i-cross die rolling kanye nomdwebo obandayo yizindlela eziphumelelayo zokukhiqiza amapayipi amise okukhethekile, afaneleka ukukhiqiza amapayipi amise okwesipesheli anezigaba ezihlukahlukene kanye nezinto zokwakha.Ukuze sikhiqize izinhlobo eziningi zamapayipi amise okwesipesheli, kumele sibe nezinhlobonhlobo zezindlela zokukhiqiza.

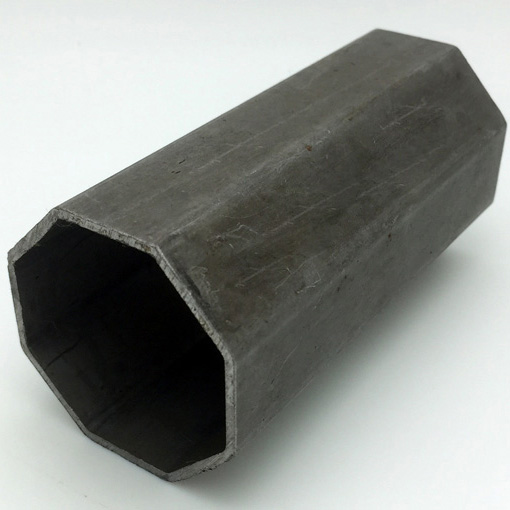

Ipayipi lensimbi elimise okweqanda elikhethekile lingahlukaniswa libe ipayipi lensimbi elimise okweqanda, ipayipi lensimbi elimise okweqanda, ipayipi lensimbi elimise okwe-hexagonal, ipayipi lensimbi elimise okwe-octagonal, ipayipi lensimbi elimise okwe-semicircular, ipayipi lensimbi eliyi-hexagon elingalingani, iplamu eyi-petal emihlanu emise okukhethekile- ipayipi lensimbi elimise okwe-convex, ipayipi lensimbi elimise okwe-concave kabili, ipayipi lensimbi elimise okwembewu yekhabe, ipayipi lensimbi elimise okukhethekile elimise okuyisipesheli kanye nepayipi lensimbi elimise okukhethekile.

Ezolimo-Pto-Polygon-Steel-Tube

Ezolimo-Pto-Polygon-Tube

I-Drive-Shaft-Steel-Tubing

I-Hexagon-seamless-steel-tube

Isikwele-Drive-Shaft-Tube

Agriculture-Pto-Drive-Shaft-Lemon-steel-Pipe-lemon-steel-tubing

Izimfuneko zokulondoloza:

1. Ngesiza noma inqolobane lapho kugcinwa khona imikhiqizo yamapayipi ensimbi amise okwesipesheli, kufanele ikhethwe endaweni ehlanzekile nehlanzekile enepayipi elibushelelezi, futhi kude nezimboni nezimayini ezinegesi eyingozi noma uthuli.Umhlabathi kufanele uhlanzwe ukhula kanye nazo zonke izinhlobo ukuze kugcinwe ukuhlanzeka kwensimbi.

2. Endaweni yokugcina impahla, akuvunyelwe ukunqwabelana nge-asidi, i-alkali, usawoti, ubumba nezinye izinto ezigqwala ensimbi.Izinhlobo ezahlukene zensimbi kufanele zihlukaniswe futhi zipakishwe ukuze kugwenywe ukudideka nokuthintana nezinto ezibolayo.

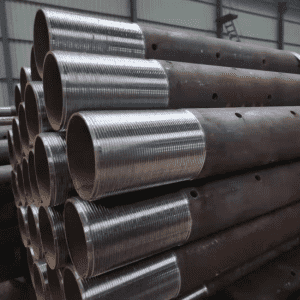

3. Amapayipi amakhulu ensimbi, ama-rails, amapuleti ensimbi, amapayipi ensimbi amakhulu amakhulu kanye nama-forging angapakishwa endaweni evulekile.

4. Insimbi yengxenye encane nephakathi nendawo, induku yocingo, ibha yensimbi, ipayipi lensimbi elinobubanzi obumaphakathi, intambo yensimbi nentambo yensimbi ingagcinwa futhi ibekwe eshede lempahla elinomoya owanelisayo, futhi kubalulekile ukumboza phezulu nephedi. phansi.

5. Insimbi encane, ipuleti elincane lensimbi, umugqa wensimbi, ububanzi obuncane noma ipayipi lensimbi elimise okukhethekile, imikhiqizo ehlukahlukene yensimbi egoqwe ngamakhaza nedonsa ngokubanda kanye nemikhiqizo yensimbi enenani eliphezulu futhi kulula ukugqwala ingagcinwa futhi ibekwe endaweni yokugcina.

6. Indawo yokugcina impahla kufanele ikhethwe ngokuvumelana nezimo zendawo, futhi indawo yokugcina impahla evamile evaliwe kufanele isetshenziswe uma kuthathwa njengefanelekile, okungukuthi, indawo yokugcina impahla enophahla olunodonga, iminyango eqinile kanye nemishini yokukhipha umoya.

7. Indawo yokugcina impahla kufanele ihlale igcina ingemuva elifanele lesitoreji, inake umoya wokungenisa umoya ezinsukwini ezishisayo, futhi ivale ukuvimbela umswakama ezinsukwini zemvula.

Isicelo

Imishini yezolimo