Ipayipi Lensimbi Esindayo

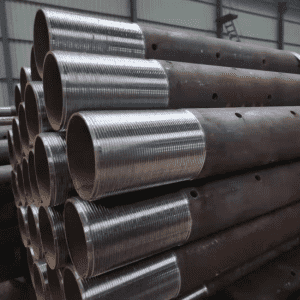

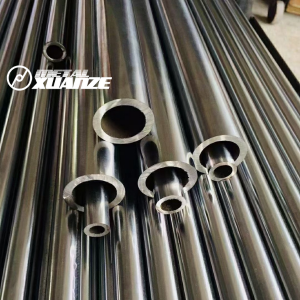

Inqubo yokukhiqiza kanye nokukhiqiza ipayipi elisindayo lensimbi engenamthungo ingahlukaniswa ngokudweba okubandayo, ukugoqa okubandayo, ukugoqa okushisayo kanye nokwanda okushisayo.Izinto zepayipi lensimbi ziyi-10, 20, 35 kanye ne-45, ebizwa ngokuthi ipayipi evamile yensimbi.Ngokusho kwesicelo, ingahlukaniswa ngamapayipi ensimbi angenamthungo, ipayipi lensimbi elingenamthungo lokuthutha, ipayipi lensimbi elingenamthungo le-boiler, ipayipi lensimbi elinomfutho ophezulu we-boiler, ipayipi lensimbi elinomfutho ophezulu wemishini yamakhemikhali kanye nensimbi engenamthungo Ipayipi lokumba le-geological;ipayipi lensimbi elingenamthungo lokumba uwoyela;ipayipi lensimbi elingenamthungo lokuqhekeka kwe-petroleum;ipayipi lensimbi elingenamthungo lomkhumbi;ipayipi lensimbi elingenamthungo elidonswa ngendlela ebandayo neligoqelwe ngokubanda;amapayipi e-alloy ahlukahlukene.Ipayipi lensimbi engenamthungo lisetshenziswa kakhulu ekucubunguleni kwemishini, imayini yamalahle, insimbi ye-hydraulic, njll.

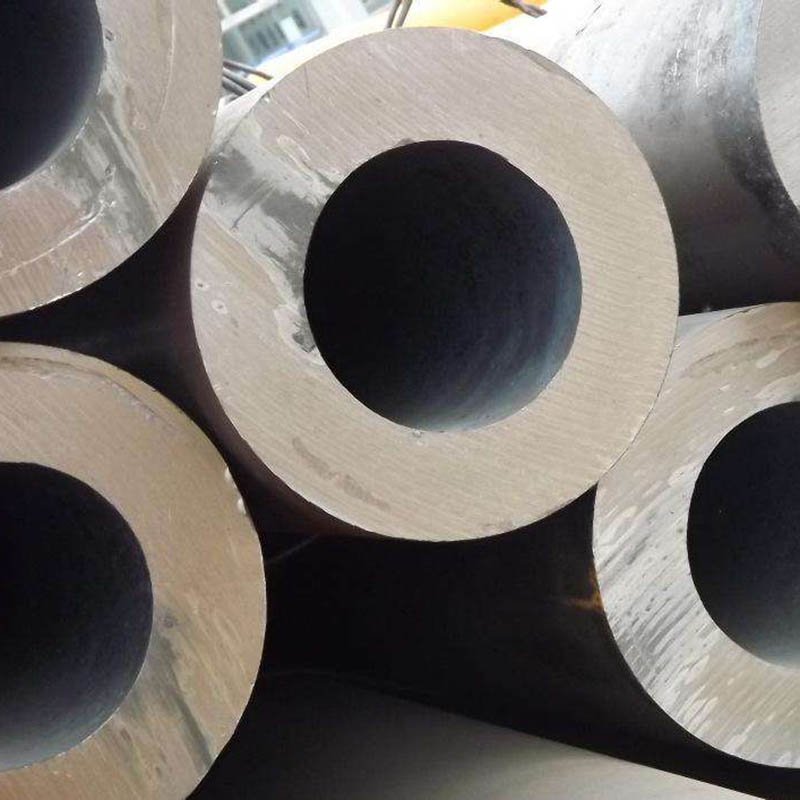

Impahla eluhlaza yepayipi eliwugqinsi lensimbi engenamthungo liyindilinga elingenalutho.I-tube eyindilinga engenalutho isikwa ngomshini wokusika, futhi i-billet enokukhula okungaba ngu-1 m ithunyelwa esithandweni ngebhande lokudlulisa ukushisa.I-billet ishiswa esithandweni esingaba ngu-1200 degrees Celsius.Uphethiloli yi-hydrogen noma i-acetylene.Ukulawulwa kwezinga lokushisa esithandweni kuyinkinga eyinhloko.Ngemuva kokuthi i-tube eyindilinga ikhishwe esithandweni, idinga ukudlula umbhobozi wokucindezela.Ngokuvamile, umbhobozi ovame kakhulu umbhobozi we-cone roll.Lolu hlobo lokubhoboza lusebenza kahle kakhulu ekukhiqizeni, ikhwalithi yomkhiqizo omuhle, ukunwetshwa kobubanzi bokubhoboza okukhulu, futhi lungagqoka amamaki ensimbi ahlukahlukene.Ngemuva kokubhoboza, i-billet eyindilinga igoqeka ngokulandelana ngokulandelana ngama-roll cross rolling, ukugoqa okuqhubekayo noma ukukhishwa.Ngemuva kwe-extrusion, i-tube kufanele isuswe ukuze ilinganiswe.Umshini wokulinganisa uzungezisa i-cone drill bit ibe insimbi engenalutho ngesivinini esikhulu ukwenza ipayipi lensimbi.

Ububanzi bangaphakathi bepayipi lensimbi bunqunywa ubude be-diameter yangaphandle ye-drill bit yomshini wokulinganisa.Ngemva kokulinganisa, ipayipi lensimbi lingena embhoshongweni wokupholisa futhi lipholiswe ngesifutho samanzi.Ngemuva kokupholisa, ipayipi lensimbi lizoqondiswa.Ngemva kokuqondisa, ipayipi lensimbi lithunyelwa kumtshina wensimbi (noma ukuhlolwa kwe-hydraulic) ngebhande lokudlulisa ukuze kutholwe amaphutha angaphakathi.Uma kukhona ukuqhekeka namabhamuza ngaphakathi kwepayipi lensimbi, kuzotholwa.Ngemuva kokuhlolwa kwekhwalithi yamapayipi ensimbi, ukukhethwa okuqinile okwenziwa ngesandla kuyadingeka.Ngemuva kokuhlolwa kwekhwalithi yepayipi lensimbi, inombolo, ukucaciswa kanye nenombolo ye-batch yokukhiqiza izofafazwa ngopende.Ikhushulelwa endlini yokugcina impahla ngokhreni.

IPHAYIPU LESINSIMBI ELINZINDAYO

Gqoka ukumelana nokuzigcoba Ukuzithambisa okuphakeme kwamakhemikhali Ubukhulu obuhlukahlukene nohlobo

Inqubo yokukhiqiza kanye nokukhiqiza ipayipi elisindayo lensimbi engenamthungo ingahlukaniswa ngokudweba okubandayo, ukugoqa okubandayo, ukugoqa okushisayo kanye nokwanda okushisayo.

Izinto zepayipi lensimbi yi-ASTM 179, A106Gr.B, 1035 kanye ne-1045, ebizwa ngokuthi ipayipi yensimbi ye-carbon evamile.

Izinto zepayipi lensimbi yi-ST52, i-ASTM 5140,4140,4135,12XMФ, ebizwa ngokuthi ipayipi yensimbi evamile ye-alloy.

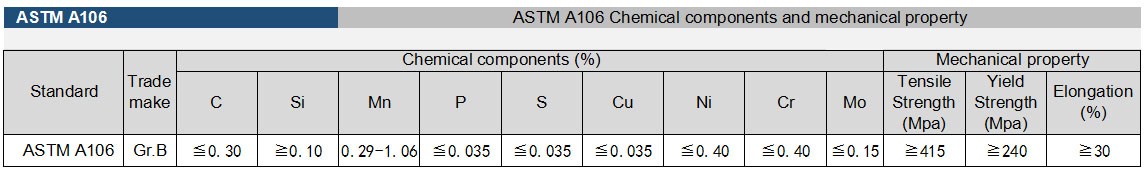

I-ASTM A106Gr.B ukwakheka kwamakhemikhali kanye nezakhiwo zemishini

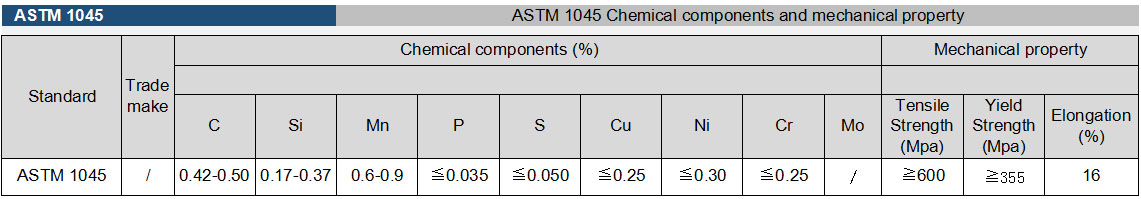

I-ASTM 1045 ukwakheka kwamakhemikhali kanye nezakhiwo zemishini

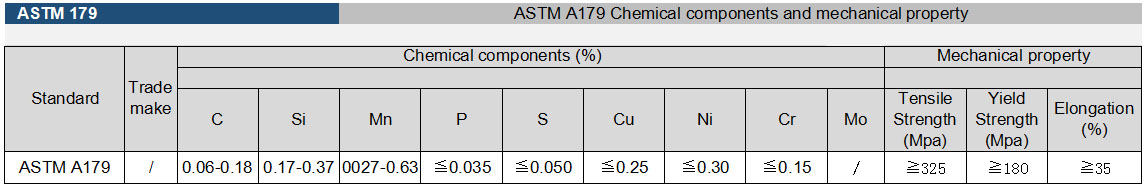

Ukwakheka kwamakhemikhali kwe-ASTM A179 kanye nezakhiwo zemishini

Ubukhulu obufanayo

I-ALLOY IMITHUNGO YESIBILI ESINDAYO