Ipayipi lensimbi elifakwe ngokushisa

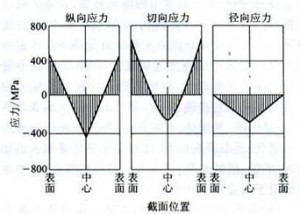

Ukwelashwa kokushisa kubhekisela endleleni yokwelapha ukushisa okukabili yokucisha kanye nokushisa okuphezulu kokushisa.Inhloso yawo ukwenza i-workpiece ibe nezakhiwo ezinhle zemishini ebanzi.Ukushisa okuphezulu kokushisa kubhekisela ekushiseni ku-500-650 ℃.Iningi lezingxenye ezishisayo zisebenza ngaphansi kwesenzo somthwalo omkhulu oguquguqukayo.Zithwala imiphumela yokushuba, ukucindezelwa, ukugoba, i-torsion noma ukugunda.Ezinye izindawo zibuye zibe nokungqubuzana, okudinga ukumelana nokugqokwa okuthile.Ngamafuphi, izingxenye zisebenza ngaphansi kokucindezeleka okuhlanganisiwe okuhlukahlukene.Lolu hlobo lwezingxenye ngokuyinhloko luyingxenye yesakhiwo semishini ehlukahlukene kanye nezinqubo, njengemigodi, izinduku zokuxhuma, izigxobo, amagiya, njll., ezisetshenziswa kakhulu kumathuluzi emishini, izimoto, ogandaganda nakwezinye izimboni zokukhiqiza.Ikakhulukazi ezingxenyeni ezinkulu ekwenziweni kwemishini esindayo, ukwelashwa kokushisa kusetshenziswa kakhulu.Ngakho-ke, ukwelashwa kokushisa kudlala indima ebalulekile ekwelapheni ukushisa.Emikhiqizweni yemishini, ngenxa yezimo ezihlukene zokucindezeleka, ukusebenza okudingekayo akufani.Ngokuvamile, zonke izinhlobo zezingxenye ezishisayo kufanele zibe nezakhiwo ezinhle kakhulu zemishini, okungukuthi, inhlanganisela efanele yamandla aphezulu kanye nokuqina okuphezulu ukuze kuqinisekiswe ukusebenza kahle kwesikhathi eside kwezingxenye.

Ukwelashwa kokushisa kwepayipi lensimbi kungenye yezinqubo ezibalulekile ekwenziweni kwemishini.Uma kuqhathaniswa nobunye ubuchwepheshe bokucutshungulwa, ukwelashwa kokushisa ngokuvamile akuguquli ukwakheka kanye nokwakheka kwamakhemikhali kwawo wonke ucezu lomsebenzi, kodwa kunikeza noma kuthuthukisa ukusebenza komsebenzi ngokushintsha i-microstructure yangaphakathi noma ukwakheka kwamakhemikhali kwendawo yokusebenza.Isici saso ukuthuthukisa ikhwalithi yangaphakathi ye-workpiece, ngokuvamile engabonakali ngeso lenyama.Ukuze wenze ipayipi yensimbi ibe nezinto ezidingekayo zemishini, ngokomzimba namakhemikhali, inqubo yokwelapha ukushisa ngokuvamile iyadingeka ngaphezu kokukhethwa okunengqondo kwezinto kanye nezinqubo ezihlukahlukene zokwakha.Insimbi iyinto esetshenziswa kakhulu embonini yemishini.I-microstructure yensimbi iyinkimbinkimbi futhi ingalawulwa ngokwelashwa kokushisa.Ngaphezu kwalokho, izakhiwo zemishini, zomzimba kanye namakhemikhali e-aluminium, ithusi, i-magnesium, i-titanium nama-alloys awo nawo angashintshwa ngokwelashwa okushisa ukuze kutholakale izakhiwo zesevisi ezahlukene.

Igama lomkhiqizo:Ipayipi lensimbi elashwe ngokushisa

Indawo Yomsuka:EShandong, eChina

Ibanga lokulawula okuqukethwe kwekhabhoni:0.30~0.50%.

Insimbi ecishiwe futhi eqinile:ASTM 1045, ASTM 5140, ASTM 4140

Izigaba zensimbi yokwelapha ukushisa:

● Insimbi ecishiwe necishiwe

● Ingxubevange yensimbi ecishiwe futhi ethambile

Ukulungiswa kokuqina:

● Ubuso obumaphakathi

● Indawo ephakathi nendawo

Ukuze uthole ukusebenza okuhle okuphelele kwensimbi efakwe ukushisa, okuqukethwe kwekhabhoni kuvame ukulawulwa ku-0.30% -0.50%.

Insimbi ecishiwe futhi eqinile:ASTM 1045, ASTM 5140, ASTM 4140

Izinhlobo: ipayipi futhi angenalutho

Ibha yensimbi yokwelapha ukushisaOsayizi:

Ububanzi bangaphandle:1/2"-24"

Ubukhulu bodonga:I-SCH10-XXS

Ubude:5.8-12Amamitha

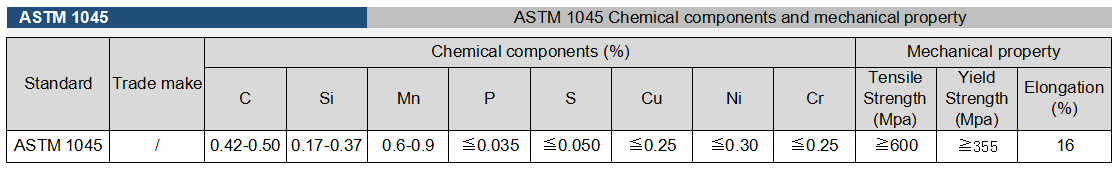

I-ASTM 1045 Izingxenye zamakhemikhali kanye nempahla yemishini:

ISICELO SE-ASTM 1045 SOKUSHISA:

Ukuqina kwensimbi engu-1045 ngemuva kokucisha: HRC 56-59

Ukushisa kokushisa: 560 ~ 600 ℃.

Izimfuneko zokuqina kwezinga lokushisa: HRC 22-30

Inhloso yokwelapha ukushisa:Comprehensive mechanical properties.

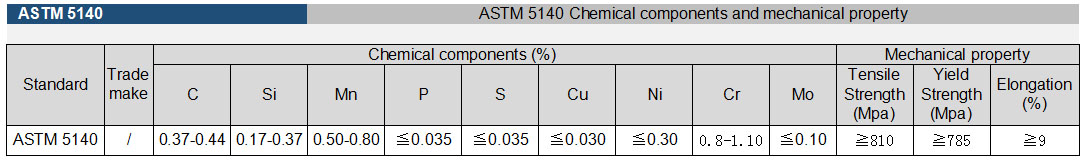

I-ASTM 5140 Izingxenye zamakhemikhali kanye nempahla yemishini:

THOLA:

ISICELO:

Ngemuva kokucisha nokushisa endaweni yokushisa ephakathi, isetshenziselwa ukwenza izingxenye ezingakwazi ukumelana nomthwalo ophezulu, umthelela kanye nesivinini esiphakathi, njengamagiya, ama-shafts amakhulu, ama-rotor futha kawoyela, ama-slider, amakholomu, njll.

I-ASTM 5140 AMAGIYA

I-ASTM 5140 IMIHLABA EYINHLOKO