Ukwelashwa Kokushisa

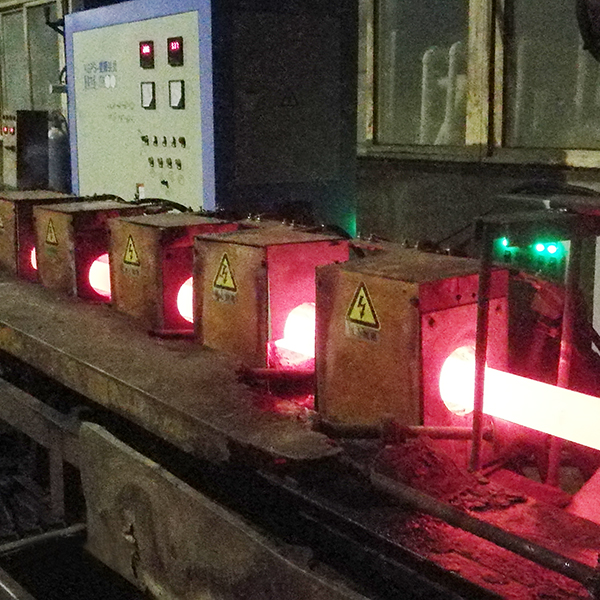

Ukwelashwa kokushisa kubhekisela endleleni yokwelapha ukushisa okukabili yokucisha kanye nokushisa okuphezulu kokushisa.Inhloso yawo ukwenza i-workpiece ibe nezakhiwo ezinhle zemishini ebanzi.Ukushisa okuphezulu kokushisa kubhekisela ekushiseni ku-500-650 ℃.Iningi lezingxenye ezishisayo zisebenza ngaphansi kwesenzo somthwalo omkhulu oguquguqukayo.Zithwala imiphumela yokushuba, ukucindezelwa, ukugoba, i-torsion noma ukugunda.Ezinye izindawo zibuye zibe nokungqubuzana, okudinga ukumelana nokugqokwa okuthile.Ngamafuphi, izingxenye zisebenza ngaphansi kokucindezeleka okuhlanganisiwe okuhlukahlukene.Lolu hlobo lwezingxenye ngokuyinhloko luyingxenye yesakhiwo semishini ehlukahlukene kanye nezinqubo, njengemigodi, izinduku zokuxhuma, izigxobo, amagiya, njll., ezisetshenziswa kakhulu kumathuluzi emishini, izimoto, ogandaganda nakwezinye izimboni zokukhiqiza.Ikakhulukazi ezingxenyeni ezinkulu ekwenziweni kwemishini esindayo, ukwelashwa kokushisa kusetshenziswa kakhulu.Ngakho-ke, ukwelashwa kokushisa kudlala indima ebalulekile ekwelapheni ukushisa.Emikhiqizweni yemishini, ngenxa yezimo ezihlukene zokucindezeleka, ukusebenza okudingekayo akufani.Ngokuvamile, zonke izinhlobo zezingxenye ezishisayo kufanele zibe nezakhiwo ezinhle kakhulu zemishini, okungukuthi, inhlanganisela efanele yamandla aphezulu kanye nokuqina okuphezulu ukuze kuqinisekiswe ukusebenza kahle kwesikhathi eside kwezingxenye.

Ukwelashwa kokushisa kwepayipi lensimbi kungenye yezinqubo ezibalulekile ekwenziweni kwemishini.Uma kuqhathaniswa nobunye ubuchwepheshe bokucutshungulwa, ukwelashwa kokushisa ngokuvamile akuguquli ukwakheka kanye nokwakheka kwamakhemikhali kwawo wonke ucezu lomsebenzi, kodwa kunikeza noma kuthuthukisa ukusebenza komsebenzi ngokushintsha i-microstructure yangaphakathi noma ukwakheka kwamakhemikhali kwendawo yokusebenza.Isici saso ukuthuthukisa ikhwalithi yangaphakathi ye-workpiece, ngokuvamile engabonakali ngeso lenyama.Ukuze wenze ipayipi yensimbi ibe nezinto ezidingekayo zemishini, ngokomzimba namakhemikhali, inqubo yokwelapha ukushisa ngokuvamile iyadingeka ngaphezu kokukhethwa okunengqondo kwezinto kanye nezinqubo ezihlukahlukene zokwakha.Insimbi iyinto esetshenziswa kakhulu embonini yemishini.I-microstructure yensimbi iyinkimbinkimbi futhi ingalawulwa ngokwelashwa kokushisa.Ngaphezu kwalokho, izakhiwo zemishini, zomzimba kanye namakhemikhali e-aluminium, ithusi, i-magnesium, i-titanium nama-alloys awo nawo angashintshwa ngokwelashwa okushisa ukuze kutholakale izakhiwo zesevisi ezahlukene.